Why Companies Are Bringing Tooling Back to the U.S.

Manufacturers across industries are moving their injection molding tools back to the United States to reduce risk and improve control.

-

Tariffs and unpredictable import costs

-

Lengthy shipping times and global logistics disruptions

-

Inconsistent quality and limited oversight

-

Difficulty communicating with offshore vendors

-

Rising sustainability and circular economy expectations

Bringing your tooling home gives you faster turnaround, higher visibility, and the ability to partner directly with a U.S. manufacturer that shares your quality standards and business values.

Cascade’s Tool Transfer Process

Transferring injection mold tooling is a multistep process that requires careful planning, technical skill, and thorough validation. Cascade’s integrated approach reduces downtime and helps you get back into production quickly.

Step 1: Evaluation and Planning

Before shipment, our team reviews your tooling documentation, part drawings, and production goals. We determine press tonnage, materials, and auxiliary requirements to identify the best-fit production cell within our facilities. Together, we’ll create a detailed transfer timeline and build an inventory plan to prevent supply interruptions during the transition.

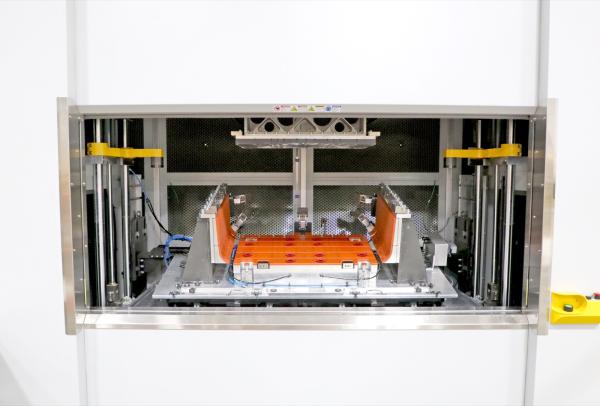

Step 2: Tool Inspection and Optimization

When your mold arrives, our technicians inspect, clean, and test every component. If we identify wear, damage, or efficiency issues, our in-house toolroom can make necessary repairs or upgrades. We also assess opportunities to improve cycle time, mold longevity, or resin performance.

Step 3: Testing and Production Launch

Once the mold is validated, we run trial shots and perform first article inspections to confirm quality, dimensions, and consistency. Our team can work with PPAP, IQ/OQ/PQ, or other qualification standards. After final approval, we ramp into full-scale production with complete process documentation and quality control.

Get a Quote on Transferring Your Tools

Interested in moving your injection molding to the United States? Reach out to the team at Cascade to set up a consultation.

How We Simplify the Transfer Process

Cascade provides everything needed to make a tool transfer successful under one roof:

-

U.S.-based logistics and production planning for faster lead times

-

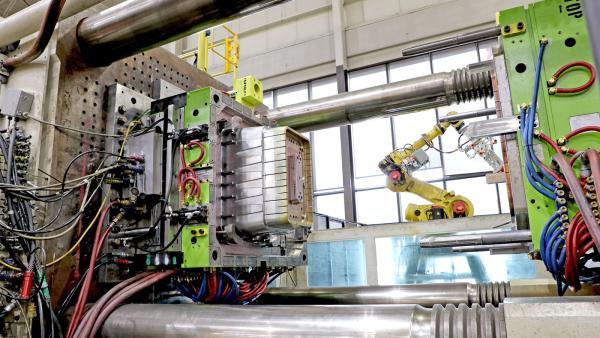

37 injection molding machines ranging from 165 to 9,000 tons

-

On-site materials lab for resin requalification and formulation adjustments

-

Full engineering, R&D, and program management support

-

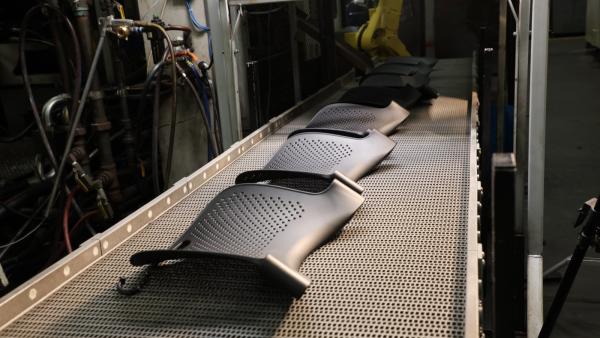

Large-tonnage capacity for parts up to 200 pounds, depending on the material

Why Partner With Cascade Engineering?

-

Advanced material and process expertise

-

Vertically integrated production capabilities

-

Proven history of successful tooling transfers

-

Capacity for high-volume and large-part programs

-

Triple Bottom Line commitment to People, Planet, and Profit

Our Services

Contract Molding

Full-service plastic injection molding for complex parts, from design support through production, assembly, and packaging.

Learn More

Waste Carts and Containers

Residential and commercial carts and containers manufactured at scale for municipalities, haulers, and private brands.

Learn More

Flood Barriers

Modular flood protection systems manufactured and supported in North America for public agencies and infrastructure owners.

Learn More

New Markets

Incubation and launch support for new plastic products in emerging markets where customers need a creative manufacturing partner.

How We Do It

Product And Market Development

Collaborative design, engineering, and business case development to help you bring new plastic products from concept to launch.

Learn more

Plastic Material Science

In-house materials lab that develops and tests resin blends for durability, sustainability, appearance, and performance.

Plastic Molding and Manufacturing

High volume injection molding with presses from 165 to 9,000 tons, plus assembly and secondary operations to deliver finished parts.

Sourcing Logistics

Program management, warehousing, and logistics coordination that help keep your supply chain stable and your lines supplied.

Industries We Work With

Automotive

Office Furniture

Produce durable, visually consistent components backed by strong materials expertise.

Infrastructure

Manufacture large structural and utility-focused parts built for long-term performance.

Material Handling

Deliver reliable bins, totes, and pallets designed for strength, safety, and repeat use.

Waste and Recycling

Manufacture rugged carts and containers that meet municipal standards and daily collection demands.

Ready to Transfer Your Tooling?

Take the first step toward a more reliable, sustainable, and cost-effective manufacturing future.

Frequently Asked Questions

Most transfers are completed in a matter of weeks, depending on mold complexity, shipping logistics, and qualification requirements. We’ll provide a project timeline before shipment so you can plan production with confidence.

Yes. Our in-house mold shop can repair, refurbish, or optimize your tooling to extend life, reduce cycle time, and improve performance.

In most cases, yes. Our team performs first article or PPAP validation runs to verify that every mold meets quality and dimensional standards before full production begins.

With proper planning, most customers experience little to no disruption in production. We help you plan inventory and logistics in advance to bridge any transition gaps.

We typically request mold drawings, part prints, resin specifications, and any previous maintenance records to begin evaluation.