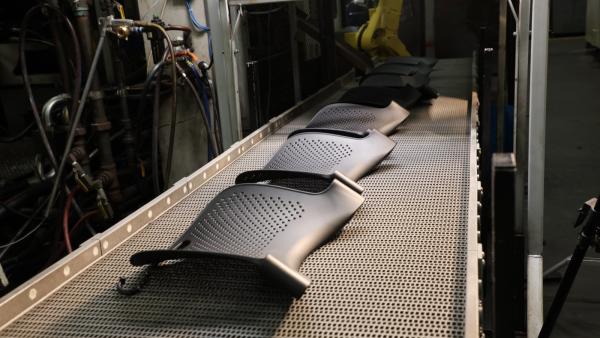

Plastic Injection Molding, Here in Michigan

-

37 presses from 165–9,000 tons

-

Part sizes up to 200 lbs with complex geometries, depending on materials

-

Specialized processes: 2-shot, co-injection, insert molding, Influx™

-

A2LA-certified material formation lab

-

Expert team with PhDs in plastics

-

Sustainable production through recycled and bio-based plastics

How We Do It

- Engineering & materials expertise: Our in-house lab tests and validates resins, including recycled and alternative fillers.

- Design & tooling: We collaborate on part design and tooling plans for cost, strength, and manufacturability.

- Production & assembly: With 37 presses, alongside our value-add assembly cells, we handle large runs with precision.

- Circular economy focus: With recycled resins and other sustainable materials, we close the loop wherever possible.

Our Service Areas

Founded in Grand Rapids and still family-led today, we continue to partner with Michigan-based businesses to advance material innovation, sustainable production, and community-focused initiatives across the state.

- Detroit

- Grand Rapids

- Warren

- Sterling Heights

- Lansing

- Ann Arbor

- Dearborn

- Livonia

- Kalamazoo

- Battle Creek

- Saginaw

- Muskegon

Why Choose Cascade Engineering?

Wide-Ranging Manufacturing Capabilities

Our Michigan-based molding operation supports projects that require materials knowledge, large-tonnage production, and high-volume reliability.

Our Triple Bottom Line: People, Planet, Profit

We build long-term partnerships, invest in our community, and look for responsible ways to reduce material waste and support a circular economy.

Woman-Owned & Michigan-Based

Founded more than 50 years ago and now led by our founder’s daughter, we bring stability, stewardship, and a forward-thinking mindset to every program.

Industries We Serve in Michigan

Automotive

High-volume molding and assembly, built for automotive production cycles.

Infrastructure

Large-format, long-life components suited for demanding infrastructure environments.

Waste Management

Reliable products for residential, commercial, and medical waste.

Materials Handling

Load-bearing, cycle-tested parts designed for high repetition and durability.

Furniture

Structural and aesthetic components produced with consistent form, fit, and finish.

Get Started with a Quote

Let’s talk through your part, your production goals, and the materials that will make it possible.

Frequently Asked Questions (FAQ)

We operate 37 presses from 165 to 9,000 tons, giving us the flexibility to mold everything from mid-size components to large, heavy parts.

Depending on the resin and geometry, we can mold parts up to approximately 200 lbs.

Yes. Our materials team frequently incorporates recycled resin, bio-based plastics, and alternative fillers to support circular economy goals without sacrificing performance.

Absolutely. We collaborate on design, tooling, and materials selection to support manufacturability and long-term production efficiency.

Yes. We offer value-added assembly capabilities to streamline production and reduce total manufacturing steps.