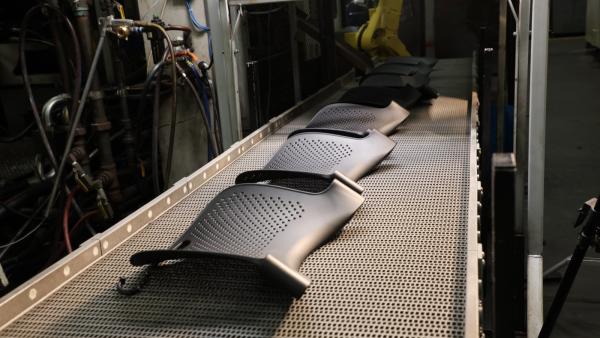

Plastic Injection Molding for Detroit Manufacturing

- 37 presses from 165–9,000 tons

- Part sizes up to 200 lbs with complex geometries, depending on materials

- Specialized processes: 2-shot, co-injection, insert molding, Influx™

- A2LA-certified material formation lab

- Expert team with PhDs in plastics

- Sustainable production through recycled and bio-based plastics

How We Do It

- Engineering & materials expertise: Our in-house lab tests and validates resins, including recycled and alternative fillers.

- Design & tooling: We collaborate on part design and tooling plans for cost, strength, and manufacturability.

- Production & assembly: With 37 presses, alongside our value-add assembly cells, we handle large runs with precision.

- Circular economy focus: With recycled resins and other sustainable materials, we close the loop wherever possible.

Why Choose Cascade Engineering?

Deep Michigan Roots

As a woman-owned, family-run company based in Grand Rapids, we’ve been part of Michigan’s manufacturing ecosystem for more than 50 years.

Materials Expertise at the Core

Our certified materials lab sets us apart and allows us to test, validate, and create resins that match performance goals.

Large-Tonnage Capacity

Detroit programs often call for high-tonnage molding, and our 9,000-ton press and broad fleet give you the capacity many suppliers cannot.

Industries We Serve in Detroit

Automotive Manufacturing

Durable interior, exterior, and structural components produced with consistent, repeatable quality.

Infrastructure Manufacturing

Large-format, high-strength parts suited for demanding infrastructure environments.

Materials Handling

Reliable components for bins, totes, pallets, and industrial handling systems.

Furniture Manufacturing

Structural and aesthetic parts delivered with smooth finishes and tight tolerances.

Waste Management

Long-lasting carts and molded components built for residential, commercial, and medical waste.

Get Started with a Quote

Bring your part, program, or concept to a Michigan team ready to support Detroit’s manufacturing needs.

Frequently Asked Questions (FAQ)

Yes. We regularly partner with Detroit-area automotive OEMs, Tier 1s, and Tier 2s, along with manufacturers in adjacent industries.

Our team typically reviews new part data within a short window. Once submitted, we’ll outline the next steps and what materials or tooling considerations may be needed.

Yes. Our high-tonnage presses support large, complex parts commonly used in automotive, materials handling, and infrastructure applications.

We do. We frequently incorporate recycled plastics, bio-based materials, and alternative fillers to support performance and sustainability goals.