How Cascade Engineering Crafts Best-in-Class Plastic Solutions

Shaping Ideas in Plastic®

Through manufacturing, product development, technology and innovation, we’re informing and transforming the products people use every day. Our use of recycled plastic in our products continues to increase year over year. Our materials and manufacturing engineering groups continually search for ways to increase recycled plastic content without impact on product performance.

Manufacturing

A Combination of Skill and Scale

6 facilities. 37 presses. This is where our expertise takes form.

From molding to assembly and finishing, we assist our customers with everything from original ideas to finished solutions. We also manufacture our own product lines. This is all done in a lean manufacturing environment, where waste is reduced and efficiency is maximized. At Cascade Engineering, we have the ability to provide a wide variety of molding processes, using the latest methods, for virtually any application.

It’s our core competency and the platform on which our manufacturing is based. Our injection molding capabilities span a full range of materials, from engineered plastics to recycled polymers. We host one of North America’s largest molding machines at 9,000 tons. With 97 molding machines ranging from 50T to 9,000T, we can mold small and large parts, allowing for complex geometries, high-quality finishing, and structural integrity.

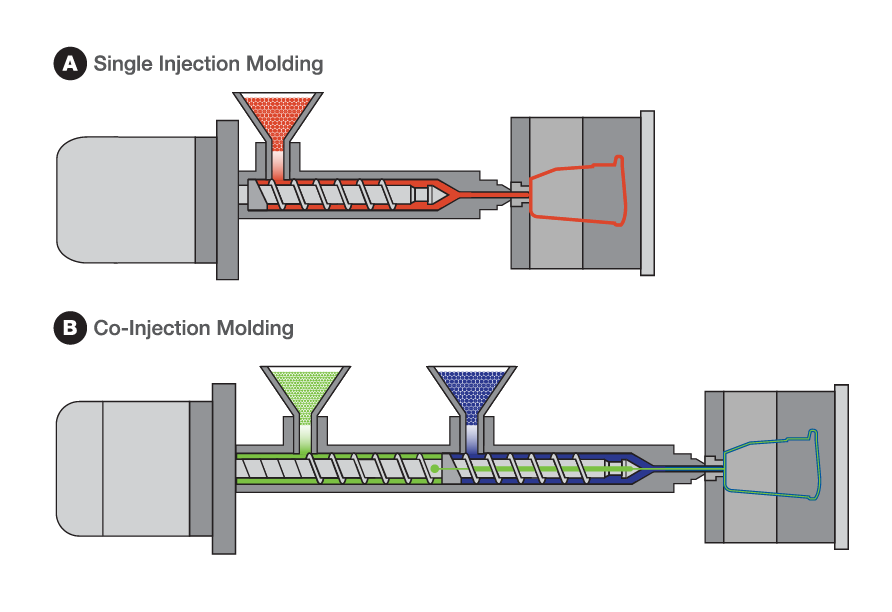

By injecting two or three materials into a mold simultaneously in specific areas, we’re able to create unique designs and functional features. Combining materials this way also creates design aesthetics, increased functionality, durability, and quality.

Injecting gas during the molding process pushes resin to the outer edge of the cavity, providing uniformity while offsetting the effects of resin shrinkage. This creates greater consistency, minimizes warp, reduces the part’s weight, and increases design freedom.

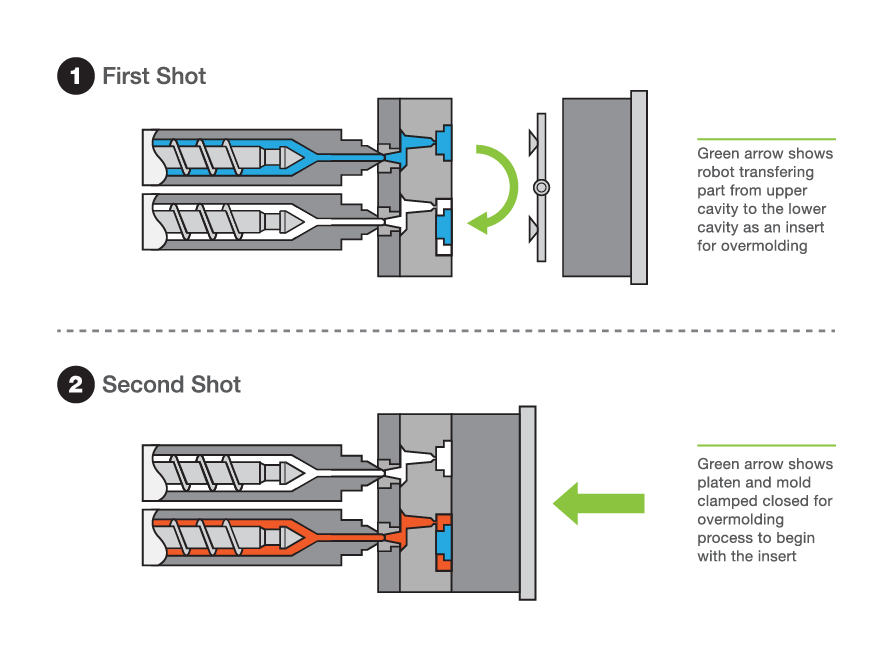

Multiple parts become a single component with the injection of thermoplastic. By creating one strongly bonded part, we can reduce assembly and labor costs, enhance design flexibility, minimize size and weight, and increase the part’s physical strength.

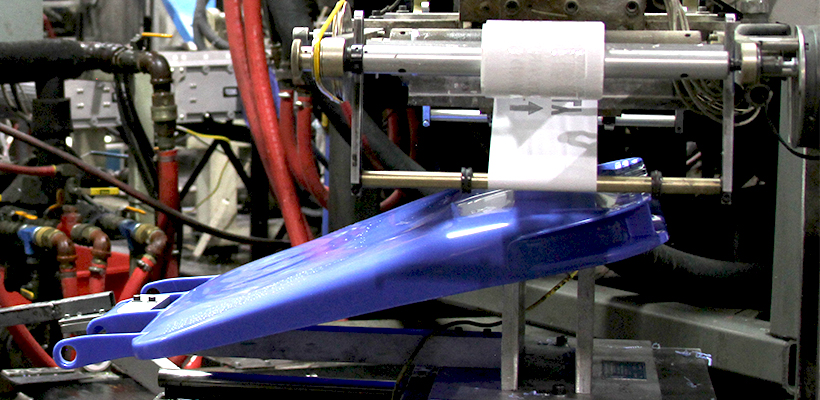

For graphics that stand out and stand up, there’s in-mold labeling. A label is placed in the mold, hot plastic permeates the label, and language/graphics become permanently integrated with the object. Years ago, we pioneered the method of in-mold barcode labels in carts, enabling better asset tracking and management in the real world.

Utilizing hot stamping, we’re able to provide information or brand identification once a product is molded. In applications like waste and recycling containers, hot stamping enables customers to display company or city logos, serial numbers, and unique program instructions.

No matter the product or manufacturing method, material matters. From recycled HDPE to our own specialty compounds, our expertise allows us to match the ideal material(s) with the design vision and end use in mind.

For specialty applications, we develop and manufacture high-performance thermoplastic materials in-house. Whether for industrial uses or consumer goods, we rise to the challenge of formulating completely customized compounds.

Assembly cells equipped with robotics, camera control units, and poke yoke systems allow the production of millions of units per year. We manufacture on a semi-automated or fully automated basis and have labeling capabilities that ensure total traceability for every assembled part.

Product Development

Giving Form to Great Ideas

From original concept to final production, we bring ambitious design visions to life.

Product development at Cascade Engineering is a disciplined process integral to our daily operation. Powered by creativity and a passion for problem-solving, we design and develop large parts, complex designs, aesthetic finishes, structural performance, and sustainable materials. We also work closely with our customers to engineer and manufacture their designs, and design, manufacture, and market our own products.

From automotive parts to iconic chairs, industrial equipment to consumer goods, we come alongside customers to set a vision for what a product or part could be. Once we know the functions and objectives, we’re able to provide solutions quickly, efficiently, and within scope.

From concept to completion, we keep customers in tune with every detail. We lean on precise quoting, PMP-certified managers, delivery tracking, and cross-functional teams to ensure transparency and active communication throughout the product development process.

Our in-house design staff is proficient in the latest CAD software and can translate to and from any CAD software package used today. From the simple to the most intricate, our team can model a product for its real-world use while benefiting from direct access to our manufacturing team.

Simulation means lower development costs, better risk management, and a faster product to market. Using the latest tools, we can evaluate possibilities and answer critical questions before a product reaches the real world, ensuring better, more predictable outcomes.

The material makes a difference. That’s why our dedicated, in-house team offers material analysis, problem solving, reverse engineering, development, testing, specification, selection, and replacement. From our laboratory, which is certified to A2LA standards, our Material Engineering Group (MEG) works with spectroscopy, microscopy, mechanical, and thermal analysis equipment to formulate ideal material solutions.

You can see and hold it before it’s manufactured. Our 3D printing and prototype capabilities provide sample parts, big or small, simple or intricate. Knowing the importance of time, we can do this very quickly, often within days.

With a breadth and depth of engineering experience, our process engineers focus on designing and controlling a product’s manufacturing. Our team's collaborative mentality allows them to identify or develop the best process for the project at hand.

Our work cells have been developed to support product, process, and production based on lean manufacturing principles. Equipped with the latest robotics and automation technology, we can increase quality and output while using part validation to control low PPM defects.

How will it perform in the real world? Will it stand the test of time? We answer these questions through a wide range of tests, including impact analysis validation, material validation assessment, thermal shock, and more.

Innovation

Encouraging a Culture of Innovation

Innovation at Cascade Engineering means being curious, daring, and questioning the status quo.

Innovation means knowing something works but being determined to improve it. It’s looking past limits and common perceptions. It’s having the courage to act on unusual ideas—especially ones that make the world better. Innovation is at the heart of everything we do, whether it’s a new method, technology, or product.

The growth of electric and hybrid vehicles in the transportation market offers exciting experiences for consumers but also demands innovative solutions for new technology applications. Cascade Engineering is collaborating with partners on a global scale to develop lightweight, cost-competitive battery components for a variety of electric vehicle markets. We offer solutions in part consolidation, fluid management, and weight reduction for products ranging from battery components to large structural enclosures.

Reducing the carbon footprint of our materials and processes is an essential responsibility for building a sustainable future. In partnership with companies like Hemp Plastic Company, UBQ Materials, and Titan Bioplastics, Cascade Engineering is integrating household waste from landfills and alternative resources into usable material in our products. Eliminating waste from the landfill reduces the amount of methane gas in the environment, and when used within our products, results in a climate-positive product. As the worldwide need for plastics grows, the planet's need for climate-positive solutions also grows.

Once China implemented the Green Fence and closed their borders to US recyclables, Cascade Engineering partnered with Waste Management and The Recycling Partnership to design a solution to the problem of recycled plastics not having a home. We created a pull in the US supply chain model by collecting mixed bulky rigid plastic from residential curbside recycling programs. We sorted it at the WM MRF, KW Plastics processed it, and Cascade Engineering reintroduced it into manufacturing and made new carts. We saved the recycled plastic from landfill and upcycled it into a brand new product of high value.

When weight reduction is key, we lend our expertise in metal-to-plastic conversion. A strategic combination of material selection, part design, feature integration, and finishing enables a successful transition from metal to plastic, reducing a part’s weight and material.

Using injection molding and specialty fibers, we can reduce noise, vibration, and harshness while creating maximum acoustic performance with the lowest possible mass. We can also integrate features such as molded-in hinges.

Fully recyclable and designed with Design for Environment (DFE) principles, our 100% recycled HDPE plastic bins are fabricated and combine strength and economy in a lightweight, one-piece design. The bin offers unsupported rack capacities up to 2,200 lbs with an evenly distributed load.

Intelligence is now encapsulated in plastic. Our RFID tags are shining examples of what happens when materials and technology are integrated as one. Today, this innovation can track resources in virtually any environment. We expect to find new and innovative uses based on our ideas and the needs of the companies we work with in the future.

Integrating plastic with technology can solve problems and make business much easier. Our most successful application is Cart Logic—a web service and mobile app designed for the waste and recycling industry. As we progress into the future, technology implementation is an area we plan on pursuing more and more.

Cascade Enterprise System (CES)

A Leaner Growth Strategy

The Cascade Enterprise System (CES) is our company-wide growth and continuous improvement strategy. Based on lean manufacturing principles and the elimination of waste throughout the organization, we take intentional steps to reach goals that once seemed unreachable. We use the A3 process to guide these steps—a systematic approach that gives structure to collaborative, in-depth problem solving.