Engineering Innovative Plastic Injection Molding & Sustainable Container Solutions

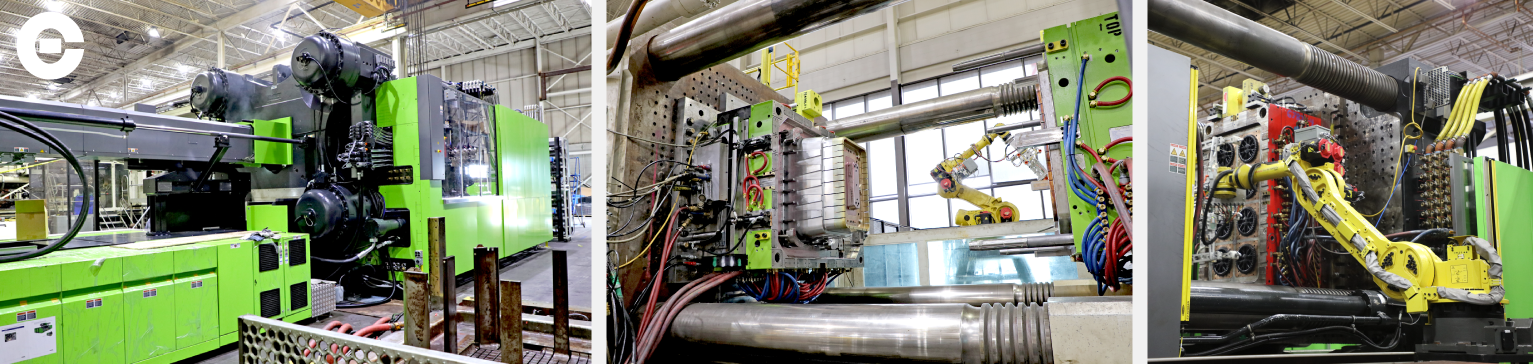

By specializing in large-tonnage plastic injection molding, we solve unique manufacturing challenges.

Collectively, we believe diversification is our strength. In service to a wide variety of industries, we share our engineering, technology, and knowledge across multiple products and industries. We take inspiration from one area, knowing it can often lead to breakthroughs in another. Our goal is to put forth products that deliver the highest value without deviating from our cultural values.

Cascade Engineering in Grand Rapids, MI is a leader in cascade injection molding, delivering precision plastic components for automotive, furniture, and industrial markets. Our advanced facilities and expert team help businesses create durable, sustainable products while keeping production efficient and cost-effective.

Business Units

Meet the Cascade Family of Companies, a group unified by our purpose and shared belief.

Separately, these three companies bring us into new worlds and ways of thinking.

With one of the world's largest fleets of large-tonnage presses and our vast engineering and technology experience, Cascade Engineering is your premier partner in containers, infrastructure, furniture, automotive, and beyond. Through diverse capabilities, multiple processes, and strong partnerships with customers, we help innovative concepts become real products.

Cascade Cart Solutions designs and manufactures high-quality waste and recycling carts, containers, and related solutions for municipalities and businesses. Our containers use RFID technology to track and manage all operations.

The material makes a difference. Based on a product’s unique requirements, we can meet the need for high-performing, eco-friendly, cost-effective compounds.

Markets

Collectively, we believe diversification is our strength. We share our engineering, technology, and knowledge across multiple products and industries in service to various markets. We take inspiration from one area, knowing it can often lead to breakthroughs in another. We aim to create products that deliver the highest value without deviating from our cultural values.

Cascade Engineering Automotive Solutions is a leader in plastic components and systems for the automotive market. Knowing the performance demands of today’s industry, we solve challenges in acoustics, functional systems, design, material selection, and manufacturing. Together with our customers, we provide part consolidation, mass efficiency, weight minimization, and cost effectiveness. From initial design and material development to final part delivery, we can handle the entire process, adding value at every step.

Around the world, we’re recognized as a problem solver in acoustics. From design and material development to full production, we have the capabilities to meet and exceed the most demanding requirements, whether the acoustic challenge lies in the engine compartment, wheel wells, or interior cockpit. Our processes and material options enable us to make everything from design-dependent dash mats to heavy-duty barriers. We also produce covers for HVAC, engines, solenoids, and manifolds.

Where our automotive expertise lies:

- 1 Acoustic Barriers

- 2 Front Trunks

- 3 Center Consoles

- 4 Window Trim

- 5 Structural Components

From pallets in automotive plants to containers for food processing applications, our material handling products are loaded with benefits. It starts with the way they’re made—from HDPE structural foam materials. This process results in durability, strength, and long-lasting performance—plus they’re reusable and require virtually no maintenance. It’s no wonder why many of the world’s most notable brands trust us to help them handle the job.

If you’ve sat in one of the world’s most celebrated office chairs, there’s a good chance we helped make it.

Together with office furniture industry leaders, we prove that art, design, science, and engineering can all work together. To create groundbreaking products, we work closely with our customers, listen to their ideas, and collaborate to make a product that is easy to manufacture and scale. Drawing from our experience and innovation history, we can enter a project at any phase, from ideation to design to tooling to production.

As acknowledged by the Industrial Design Society of America (IDSA), we’ve played a major role in the development of Herman Miller’s three most recent “Chairs of the Decade”—Equa, Aeron, and Setu.

Can thermoplastic solutions be both high-performance and eco-friendly? Absolutely.

When product concepts collide with material needs, we create compounds that outperform expectations. With substantial compounding expertise, our team has taken an eco-focused approach and turned it into an industry-leading reputation. In addition to formulating and producing specialty compounds, we provide a full line of olefin—and elastomer-based compounds.

Using the latest compounding equipment, we produce stock and customized materials for medium-to high-volume applications in the automotive, office furniture, and consumer goods industries.

Where durable material meets the latest technology.

Years ago, we received a request to create an RFID tag for two-wheeled residential recycling containers. We learned the application, tested designs, and developed a tag to meet the stringent requirements of the municipal solid waste industry. Extreme temperatures, seasonal weather, multiple impacts, and substantial vibration were all accounted for. Once designed, the RFID tags snapped into position, and assets could be tracked at a moment’s notice.

It began with RFID tags, but today, we’re exploring new and ambitious ways to combine injection molding with the latest technology. From asset management to smart sensors, we’re devising new ways to help businesses run faster, smarter, and more efficiently.

We’ve been manufacturing containers since 1989, with over 30 million in the market today.

We’ve been producing carts for residential and commercial use. Our history of developing long-term partnerships with our customers while also focusing on the greater good of the environment has led to the creation of numerous technology products and services that complement our collection container product line.

The EcoCart

Here in the US, we have the very real problem of not being able to export our plastics to China any longer. The situation has created market disruptions, threatened municipal recycling programs coast to coast, and caused havoc in the market. At Cascade, we’re taking action. We have worked with our customers and designed a closed-loop system that utilizes residential curbside plastic, bulky rigid plastic straight out of your recycling program, and into our carts.

Put another way, we have created domestic demand for genuine post-consumer plastic. We are proud to introduce the EcoCart manufactured with 10% plastic right off the curb, offering the same price, same warranty, NO compromise!

The Pink Cart

With every purchase of The Pink Cart, $5 goes directly to the American Cancer Society® to support breast cancer initiatives both locally and nationally. With over 140,000 Pink Carts rolling to curbs weekly, Cascade has helped provide ACS with over $750,000 in funds.

Beyond our direct contributions, each participating Pink Cart hauler has the opportunity to make an impact in their local community. Learn more at thepinkcart.com.

Field Service Management

Less downtime = happier customers—that’s the goal we help you achieve. Our team can work with you to establish a Service Center at your location. From curbside distribution to inventory of new and refurbished carts, repair activities, and eventual recycling, we take care of all activities related to your residential cart base so that you can focus on your collection and processing operations.

CartLogic

CartLogic is the latest generation of asset management software—designed specifically for and by the waste industry. By taking advantage of RFID technology, CartLogic empowers full control and responsive service from the convenience of a web-based portal and free mobile app.